Dear readers

The automotive industry is undergoing a transformative evolution, fuelled by the integration of Artificial Intelligence (AI). Once considered a futuristic concept, but traditionally slower in adopting cutting-edge technology compared to sectors like finance and healthcare, the automotive sector is now embracing AI as a critical enabler of innovation. AI is now the cornerstone of innovation, reshaping vehicle design, production processes, and customer interactions. The integration of AI is transforming the industry into a smarter, safer, and more sustainable ecosystem, promising a future defined by unparalleled convenience and efficiency.

AI in Automotive: From Theory to Application

AI has evolved from theory to a transformative force in the automotive industry, revolutionizing mobility and efficiency.

Realized AI powers technologies like Tesla’s Autopilot and predictive maintenance tools, addressing real-world challenges with advanced driver assistance and operational insights.

Theoretical AI, including Artificial General Intelligence (AGI) and Artificial Superintelligence (ASI), promises vehicles capable of reasoning, emotional adaptation, and ethical decision-making. However, these remain experimental, with significant technical and ethical hurdles.

AI Capabilities:

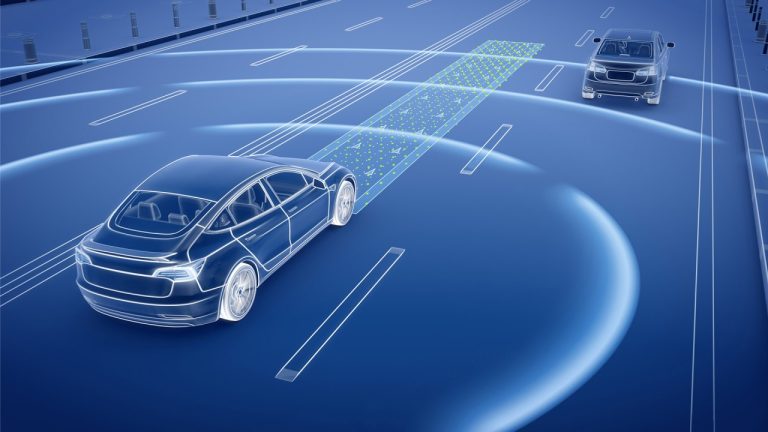

- Narrow AI drives current innovations with specialized functions like collision avoidance and autonomous navigation.

- AGI aspires to human-like reasoning for advanced personalization and decision-making.

- ASI, though theoretical, envisions surpassing human intelligence, offering opportunities but raising profound ethical concerns.

AI is reshaping the automotive landscape, bridging the gap between innovation and future possibilities while presenting challenges that demand careful navigation.

AI’s Role in Transforming the Automotive Industry

- Smart Cars: Personal Co-Pilots

Modern vehicles are evolving into intelligent companions. AI-driven personalization systems adapt to driver preferences, offering customized music, navigation, and climate settings. These features create a more engaging and user-centric experience. - Autonomous Driving:

A Safer Journey

Autonomous vehicles are the epitome of AI’s potential in mobility. Companies like Tesla and Waymo leverage sensors, cameras, and machine learning to enable self-driving cars that navigate urban complexities. AI also enhances safety with predictive algorithms that preemptively avoid hazards. - Predictive Maintenance:

Proactive Care

AI-driven diagnostics monitor vehicle health, detecting issues before they escalate. For EVs, this includes battery degradation predictions, while for ICE vehicles, it monitors engine performance. This approach reduces breakdowns and extends lifespans. - Smarter Manufacturing

AI streamlines production processes by automating repetitive tasks, reducing errors, and optimizing resource allocation. Consumer trend analysis helps manufacturers design vehicles tailored to evolving market demands. - Connected Cars in IoT Ecosystems

AI enables vehicles to communicate with smart infrastructure, improving traffic flow and safety. However, this increased connectivity demands robust AI-powered cybersecurity solutions to mitigate threats.

Transforming Aftersales Services with AI

Aftersales services are a critical touchpoint for customer satisfaction, and AI is revolutionizing this domain by streamlining operations, improving diagnostics, and enhancing customer experiences.

- Predictive Maintenance

AI systems monitor vehicle health through sensors, identifying potential issues before they become significant. For EVs, this includes predicting battery degradation, while for ICE vehicles, it monitors engine wear and tear. This proactive approach minimizes emergency repairs and builds trust.

2. Automated Diagnostics

AI-driven tools diagnose vehicle problems with precision and speed. These systems can identify faults in EV drivetrains or traditional ICE systems, enabling technicians to resolve issues more efficiently.

3. Efficient Parts Management

AI optimizes inventory by predicting demand for spare parts, ensuring timely availability. This reduces vehicle downtime and enhances customer trust in service centers.

4. Personalized Service Schedules

By analyzing driving patterns, AI creates tailored maintenance schedules. Customers benefit from optimized service intervals, avoiding unnecessary visits while ensuring reliability.

5. Enhanced Customer Relationships

AI-powered CRM tools, such as chatbots and predictive analytics, improve communication and provide personalized solutions. Proactive alerts for maintenance and service reminders foster stronger customer relationships.

6. Streamlined Insurance Claims

AI simplifies insurance claims through automation, reducing processing times and improving transparency. Predictive models also help prevent fraudulent claims.

Challenges of AI Adoption in Aftersales and Beyond

- Workforce Transition:

Automation risks job displacement; upskilling technicians is essential.

2. Algorithmic Bias:

Faulty data can lead to inaccurate diagnoses and erode trust.

3. Data Privacy:

Protecting sensitive customer data in connected systems is critical.

4. Cybersecurity:

AI-driven services face cyber-attack vulnerabilities, demanding robust security.

5. Ethical Dilemmas:

Liability in autonomous driving and opaque AI decisions challenge trust.

- Over-Reliance on AI:

Excessive automation risks diminishing human problem-solving skills.

Embracing AI for a Sustainable Automotive Future

- Workforce Development:

Train teams to effectively use AI tools. - Data Security:

Invest in advanced cybersecurity to protect customer information. - Quality Control:

Ensure AI systems are reliable through rigorous testing. - Ethical Standards:

Create frameworks for transparent and accountable AI operations.

Key Note:

AI is Driving the Next Generation of Mobility

Artificial Intelligence (AI) is reshaping the automotive industry, driving the next generation of mobility.

Far from being a mere trend, AI represents a paradigm shift that is revolutionizing smart cars, autonomous driving, and aftersales services. With its potential to unlock unprecedented opportunities for innovation and growth, AI is setting the stage for a smarter, safer, and more sustainable future of mobility.

However, this transformation is not without challenges, as the industry must address workforce adaptation, data privacy, and ethical concerns to fully harness AI’s benefits.

The integration of AI is significantly impacting the job market, automating repetitive tasks and reshaping roles across industries. Jobs involving data entry, telemarketing, assembly lines, and basic bookkeeping are particularly vulnerable to automation.

In customer service, AI-powered chatbots and virtual assistants are replacing traditional roles, while autonomous vehicles pose a threat to transportation jobs. Similarly, manufacturing, logistics, and retail sectors are witnessing the rise of robots and automated systems that are streamlining operations but reducing the need for human intervention.

Yet, AI is not just a job displacer—it is also a creator of opportunities. It is driving demand for new roles in AI development and maintenance, such as machine learning engineers, data scientists, and AI trainers.

Emerging fields like robotics, cybersecurity, and renewable energy are also benefiting from AI advancements, while creative and strategic industries are leveraging AI-enhanced tools for design, marketing, and content creation. Furthermore, the need for AI ethics and regulation is giving rise to specialized roles to ensure its responsible use.

The overall impact of AI on jobs is a mix of displacement and creation. According to the World Economic Forum, AI could displace 85 million jobs globally by 2025 but create 97 million new ones. PwC predicts that around 30% of jobs may be at risk of automation by the mid-2030s, with low-skill roles being the most affected.

To navigate this transformation, it is crucial for businesses, governments, and individuals to invest in upskilling and reskilling efforts, ensuring that the workforce is prepared for the evolving job landscape.

For automotive leaders, the key lies in balancing innovation with responsibility. Companies that embrace AI’s potential while addressing its challenges will not only lead the industry but also set benchmarks for its ethical and sustainable implementation.

The road ahead is clear: AI is the driving force behind the automotive industry’s evolution. The question is no longer whether AI will reshape the world of mobility—but how quickly it will accelerate us into a future defined by intelligent, innovative solutions.

First published in Automark Magazine: Driving Innovation, Empowering Mobility

Exclusive written by Asif Mehmood for Automark’s December-2024 printed and digital edition.