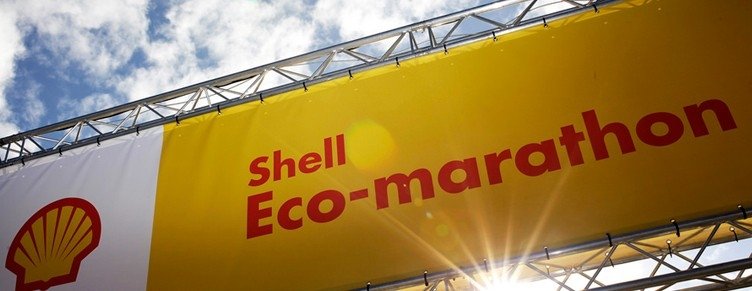

Karachi (Feb 12, 2019):Shell announced today that Malaysia will host Shell Eco-marathon Asia in 2019 as part of its global Make the Future Live programme. Held at Sepang International Circuit, Kuala Lumpur, the Asia competition comes back to where it was first held in 2010, and celebrates its 10th year of challenging bright young student minds to design and build ultra-energy-efficient cars, and then take them out on the track in competition.

From April 29 to May 2 over100 teams from all over Asia and the Middle East will test their self-built energy-efficient cars in the Shell Eco-marathon Mileage Challenge, to see who can go the farthest using the least amount of energy. In 2018 Singapore hosted the event, where the winning team was efficient enough to travel 2,341 kilometres – about the distance from Malaysia to Yangon, Myanmar – on just one litre of fuel!

“Shell Malaysia is proud to host the 10th Shell Eco-marathon Asia at our home ground. It is an inspiring event that supports Shell’s vision of sustainable mobility – more energy efficient vehicles and cleaner road transport. It’s really impressive to see student teams pitting their skills against their cohorts from different countries to see who can design and build the most fuel-efficient vehicle,” explained Iain Lo, Chairman of Shell Malaysia.

“Shell has been in Malaysia for over 125 years, and we will continue to power Malaysia’s future with cleaner, innovative and competitive energy solutions, some of which will be showcased at the event,” he further added.

Student teams will also have the opportunity to qualify for the Shell Eco-marathon Drivers’ World Championship. Introduced to the Shell Eco-marathon programme in 2016, Drivers’ World Championship challenges the best UrbanConcept teams to combine the proven energy efficiency of their car with the speed and skill of their driver, in a race to see who can cross the finish line first on the least amount of fuel. Qualified teams will go to London for a chance to compete with teams from Europe and the Americas. In 2018, ITS Team 2 from Indonesia’s InstitutTeknologiSepuluhNopember Surabaya was crowned the ultimate global winner of the Drivers’ World Championship, the second Asian team to win in the three years the competition has been running.

Pakistan will again be participating in Shell Eco-marathon Asia, with a contingent of10 futuristic cars from 6 universities competing to be the most energy-efficient. Last year, a team from National University of Sciences & Technology (NUST) earned the ‘Perseverance and Spirit of the Event’ Award for helping other teams compete in the race. This year the teams are more spirited and determined to bring home a race award.

”Every year, we see an increasing standard of performance, as well as team spirit and passion, among the student participants at Shell Eco-marathon Asia. The Sepang International Circuit in Malaysia is the perfect venue to witness new innovations in vehicle design come to life. We look forward to another exciting year at Shell Eco-marathon Asia,” said Shanna Simmons, Shell Eco-marathon Global Technical Director

For more information on Shell Eco-marathon Asia 2019, please visit: https://www.shell.com/make-the-future/shell-ecomarathon/asia.html

ENDS

About Shell Eco-marathon

Shell Eco-marathon can be traced back to 1939 at a Shell research laboratory in the United States as a friendly wager between scientists to see who could get the most miles per gallon from their vehicle. The winner of that contest barely achieved 50 mpg (21 km/l). These humble origins inspiredwhat is now a global programme of competitions. In 1985 in France, Shell Eco-marathon as we know it today was born. In April 2007, Shell Eco-marathon Americas event was launched in the United States, and in 2010, the inaugural Shell Eco-marathon Asia was kicked off in Malaysia.

Malaysia hosted Shell Eco-marathon Asia from 2010 until 2013. In 2014, the event moved to a street circuit in Manila, Philippines, which hosted the event until 2016. Shell Eco-marathonAsia then moved to Singapore at the Make the Future Festival from 2017 to 2018. This 2019, in its 10th year, Shell Eco-marathon Asia returns to the Sepang International Circuit in Kuala Lumpur, Malaysia.

ENQUIRIES:

Cindy Lopez

Head, South East Asia/South Asia, Media Relations

[email protected]

MichVillar

Shell Spokesperson

[email protected]

Elaine Villanueva

Shell Spokesperson

[email protected]