Infection surges in Southeast Asia threaten global supply chains

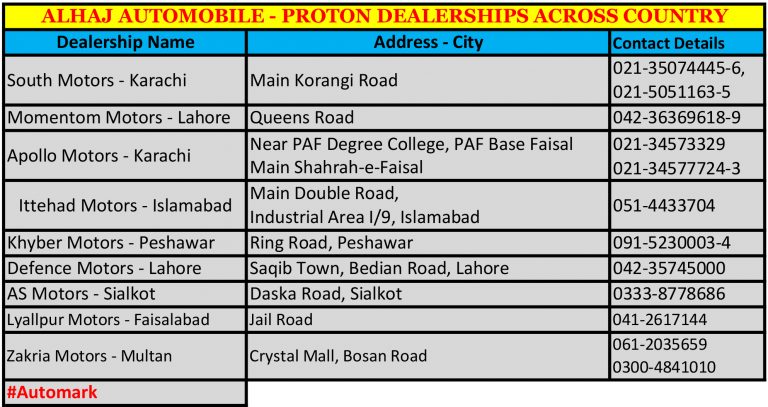

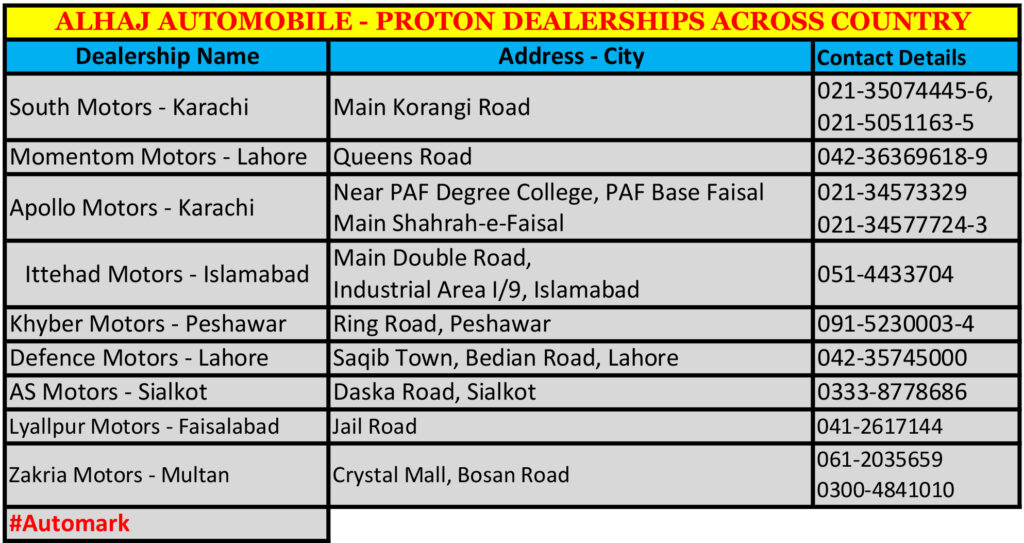

Due to the commencement of the Movement Control Order (MCO) from 1 June-14 June 2021, sales activities at all PROTON outlets will temporarily cease starting Tuesday, 1 June.

Our service centres will continue to operate, and servicing of vehicles will be by appointment only. Bookings can be made by calling individual service centres or via the MyProton app. Walk-in customers will not be entertained.

For emergency cases, please contact our Customer Care hotline, for urgent assistance (available 24-hours). For inquiries, please send us an e-mail.

Malaysian automakers Proton may shut their production plant of SAG, X-70 and X-50 as Toyota Motor and Honda Motor already shut down production in Malaysia from 1st June, as the nation goes into a lockdown, raising concerns that surging coronavirus cases in Southeast Asia will cripple global supply chains.

Supply of Proton products including CBU units and CKD to Pakistan already effected due to pandemic and now this current lockdown will brings more halt, while production facilities equipments and other necessary plant related machinery may delay too.

According to official announcement at Proton website “Due to the commencement of the Movement Control Order (MCO) from 1 June-14 June 2021, sales activities at all PROTON outlets will temporarily cease starting Tuesday, 1 June.

Our service centres will continue to operate, and servicing of vehicles will be by appointment only. Bookings can be made by calling individual service centres or via the MyProton app. Walk-in customers will not be entertained.

For emergency cases, please contact our Customer Care hotline, for urgent assistance (available 24-hours). For inquiries, please send us an e-mail.”

Malaysia imposes a nationwide lockdown on Tuesday, shutting most industries through June 14. Auto manufacturers and steelmakers will be permitted to continue operating but may send only 10% of their employees to work, while electronics, chemical and pharmaceutical companies will be limited to 60%.

Malaysia, Thailand and Vietnam, countries that previously avoided the worst of the pandemic, are now seeing rapid increases in infections. The region serves as a key manufacturing hub for intermediate goods as companies shift production away from China. Now the surging cases are threatening to disrupt global manufacturing.

PROTON in April-21 began work on a further addition to their Tanjung Malim plant. The company performed a ground breaking ceremony for a new stamping facility that will complement the existing lines. This expansion will house a new Super large press machine to further enhance stamping abilities. More significantly, it is part of PROTON’s overarching plan to increase levels of localisation, both for current and future models.

With an investment of RM 200 million, this new facility is part of PROTON’s plan to make Tanjung Malim a world class manufacturing plant. This is on top of the RM 1.2 billion that was spent previously. The new press will allow for the stamping of much larger pieces of bodywork and other parts.

The company says that this investment is part of its growth strategy as well as for future planning as it is designed to allow for the manufacturing of more model lines. It is also in line with PROTON’s technology strategy as the new area will include state-of-the-art tools as well as systems.

New daily infections in Malaysia have nearly doubled over the past week as low vaccination rates lead to the spread of contagious variants. Reported cases reached a record of 9,020 on Saturday, or more than 200 per 1 million people — a higher rate than in India, which has only recently shown signs of improvement from one of the world’s worst outbreaks.

Infections have trended upward in Thailand since March, when a cluster of cases tied to a more infectious variant first found in the U.K. was detected in a Bangkok nightlife district. Taiwan’s New Kinpo Group halted operations at a printer and telecommunications equipment factory in Thailand on May 20 after an outbreak was detected there.

Meanwhile, a “hybrid” with traits from the U.K. and India variants has been found in areas of northern Vietnam that are packed with industrial parks, and authorities are increasingly worried about the threat to supply chains.

Thailand is the region’s largest car manufacturing hub, from which Toyota and other Japanese automakers export finished vehicles to elsewhere in Southeast Asia as well as markets in the Middle East and Oceania. Vietnam is a top manufacturing center for Samsung Electronics, supplying handsets to markets as distant as Europe and the U.S.

In Thailand, a few factories on the end of supply chains were forced to close due to outbreaks among workers. Medical glove manufacturer Sri Trang Gloves shut its plants indefinitely in the southern cities of Trang and Surat Thani on orders from authorities, after 41 employees tested positive for COVID-19.

The company had benefited from higher demand for latex gloves during the pandemic. The two factories have a combined production capacity of 1.9 billion pieces per year, accounting for around half of Sri Trang Gloves’ total capacity.

Charoen Pokphand Foods, the food-processing arm of Thailand’s largest conglomerate, is closing a poultry processing plant roughly 100 km north of Bangkok for five days until Thursday. Two hundred forty-five out of 5,800 workers at the closed plant had tested positive as of Sunday. CP Foods’ 18 other food-processing and feed factories will continue operating as normal, according to the company.

The 10-member Association of Southeast Asian Nations has become an increasingly important producer and exporter of intermediate goods in recent years. The annual added value of exports from nine ASEAN members more than doubled in the decade through 2019, according to Mizuho Research & Technologies, the sharpest rise among the five main global regions studied. The region held a 10.5% share of this added value.

Asia had endured fewer coronavirus cases than the U.S. and Europe until recently. But the region recently reported more than 210,000 new daily infections, more than 40% of the worldwide total, with slow vaccine rollouts seen as a major factor.